Kaiser 250 Ton press installed

In the stamping department, a Kaiser 250 Ton press has been installed. This machine was bought second hand, and overhauled by ourselves. Our partner Smits Besturingstechniek BV took care of the electrical overhaul. With the aid of this press, it is now possible to apply tools with a length of 1300 mm.

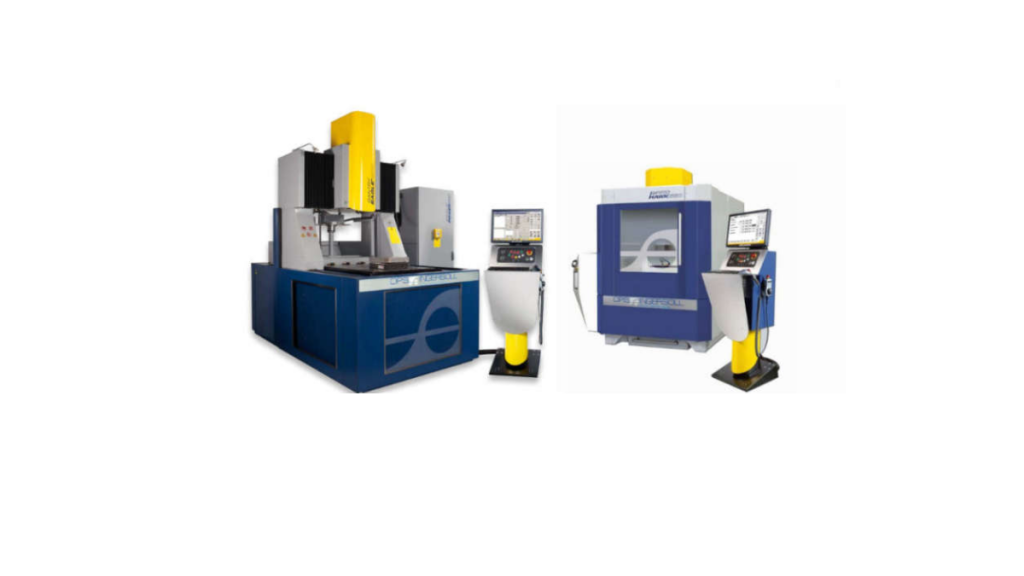

Renewal sink erosion and electrode machining

We had a great opportunity to invest in a combination of OPS Ingersoll, a Speedhawk 550 High speed milling machine, and a sink eroding machine Gantry 800 for our Toolshop. With this investment, our sink erosion jobs are future proof.

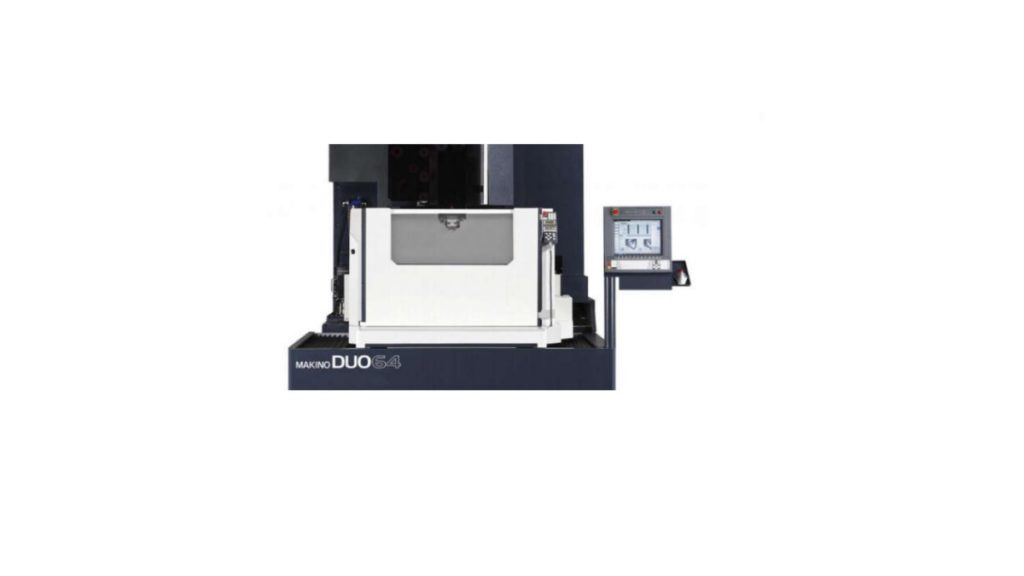

Additional wire erosion machine

In onze gereedschapmakerij is er een Makino Duo 64 bijgekomen, om de toegenomen werkhoeveelheid aan te kunnen. We hebben van Makino reeds 2 freesbanken, waar we zeer tevreden over zijn in gebruik, betrouwbaarheid en nauwkeurigheid, en op die grond ook besloten om ook een draadvonker van dit fabricaat aan te schaffen.

Publication Euro-Techniek

In the customer magazine of our accountant – Joanknecht, the attached article is published on Euro-Techniek. Besides the panorama of the toolshop, also our innovations on robotics and vision are highlighted in the – dutch – tekst. Item Joanknecht

Press line collected from customer

An existing customer of Euro-Techniek,a well known german automotive supplier did have one press line in operation. Recently they have selected Euro-techniek to take over this press line, including the manufacturing of the associated parts. As preparation, our operators have trained at the customers site for two days together with the personell of the customer. […]

New facade advertisings

In September 2016, we added the building de Run 4311 and de Run 4313 to our premises. Since that moment, in a number of smaller and larger jobs, we started to use these buildings as intended. Almost three years later, as a moment of closure, we added two lighted facade advertisings to these buildings.

2K Molding unit

For some time now Euro-Techniek manufactures 2K products. For a new project, deliberately is chosen to combine a Boy 2K molding unit with an existing Arburg machine. As the Boy unit easily can be adapted to another machine, we now have the flexibility to make 2K products also on other machines.

Hannover Messe

Also this year, Euro-Techniek was exhibiting at the Hannover Messe. In the attached article from the house magzine of the MetaalUnie (our Dutch employers association) a nice review of the Dutch “Holland Stand”. Item Metaalunie

In coöperation between Euro-Techniek and Mikrocentrum a training course for press operators was started

In coöperation between Euro-Techniek and Mikrocentrum a training course for press operators was started. This course is based on a Philips course from a long time ago, which at that times started two times per year. Now, the course has been renewed by the teachers, and at Euro-techniek, this course is now given, with participants […]

Engineer at Euro-Techniek, joins the BBL-4 course “engineering technician”

Eef van Berkel (far right on picture), Engineer at Euro-Techniek, joins the BBL-4 course “engineering technician” at ROC Tilburg. Currently, she is in het third year. When our king Willem-Alexander visited the ROC, Eef was introduced to him as a typical example of adult education.