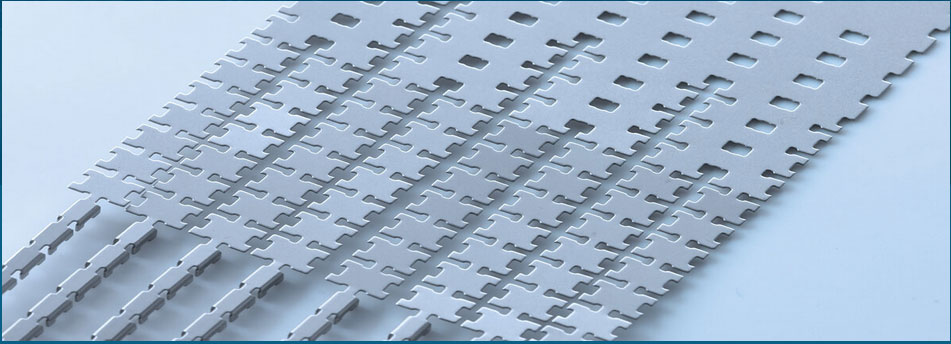

Stamping

Quality and delivery reliability are key goals in our stamping department. It is what our demanding customers in the automotive, food, baby care, HVAC, electronics, medical and life sciences industries expect of us.

Having an internal engineering department and a tool shop is a big advantage when it comes to producing products with high precisions and small tolerances. It enables us to detect and correct problems as soon as they occur, or to find an alternative solution.

Our stamping department is equipped with an eccentric stamping machine of 5 to 160 tons, eccentric C-frame presses from 25 to 125 for manual stamping and automation, as well as a few hydraulic presses. The products we make vary in size and range from a pin head to a shoe box in thicknesses from 0.03 mm to 6 mm. We process a wide range of materials such as Ferro (steel, stainless steel, cold-rolled steel), copper and its alloys (such as brass, bronze and new silver), as well as light metals such as aluminum, magnesium and titanium and rare metals such as pure nickel and pure molybdenum.

Products can be delivered in bulk, reels, or cartridges. We produce series consisting of a few pieces to millions of pieces.

Our stamping department has a washing machine and Roto-Finish equipment to clean the products. We can assemble your products mechanically or by spot welding.

Visitor’s address

De Run 4311

5503 LP Veldhoven

Delivery address

De Run 4313

5503 LP Veldhoven

Postal address

Postbus 283

5500 AG Veldhoven

Tel: 0031 (0)40 2539995

Fax: 0031 (0)40 2539255

E-mail

info@euro-techniek.nl

Stamping media